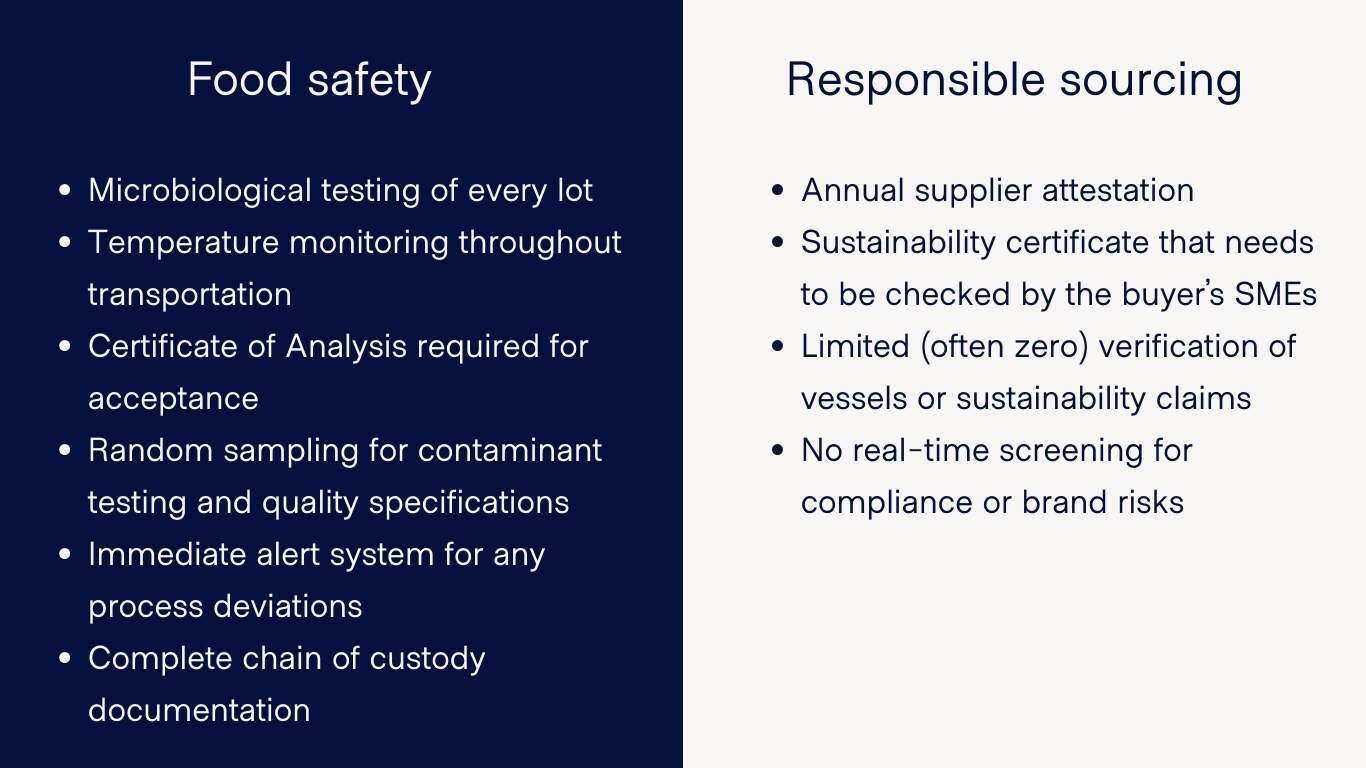

In my last post I highlighted a striking disconnect in the food industry: In food safety, companies invest in advanced systems to manage risk. But when it comes to sustainable sourcing, compliance is still often treated as a paperwork exercise—even as requirements grow stricter and shift from brand values to binding contracts.

Why the double standard?

Just as FSQA evolved to meet rising regulatory and brand risks, sustainable sourcing now demands the same level of rigor—and manual checks can’t keep up. So what does a modern, tech-driven solution look like? Let’s break it down—with a side-by-side view of today’s reality.

This disparity creates significant blind spots and risks. The same shipment that is meticulously verified for food safety and quality controls either bypasses scrutiny for sustainability and ethical sourcing concerns—or if resources and expertise permit, someone is saddled with a slow, stressful manual review.

What would we see if sustainable sourcing verification was treated with the same seriousness as food safety?

1. Real-time validation, not annual attestation

Just as you wouldn't wait a year to discover a pathogen contamination, you shouldn't wait a year to learn about IUU vessels in your supply chain, or the product you are receiving as MSC certified is not actually MSC certified. Verification needs to happen at the transaction level, not the annual report level.

2. Risk screening

Not all suppliers and products carry the same risk profile. Sophisticated FSQA systems apply more scrutiny to higher-risk ingredients and processes. Sustainable sourcing verification should do the same, focusing resources where risks are greatest. Properly structured data — verified in real time allows for sophisticated analytics — making real-time risk-based screening possible.

3. Supplier empowerment

Effective food safety systems don't just punish non-compliance and immediately cut off suppliers; they investigate, formulate corrective actions and help suppliers improve to support more opportunities to access compliant raw materials and retail products. The same collaborative approach should apply to sustainable sourcing, providing suppliers with tools to meet requirements, risk-based screening, investigations when necessary, corrective actions when necessary, ongoing feedback and support, rather than just auditing failures.

4. Data validation and analysis

Food safety systems don't just collect data; they verify it, analyze it, validate their preventative controls using it, and generate actionable insights for continuous improvement. “Traceability” technology must go beyond simply collecting and storing data to validating their accuracy and identifying patterns and risks.

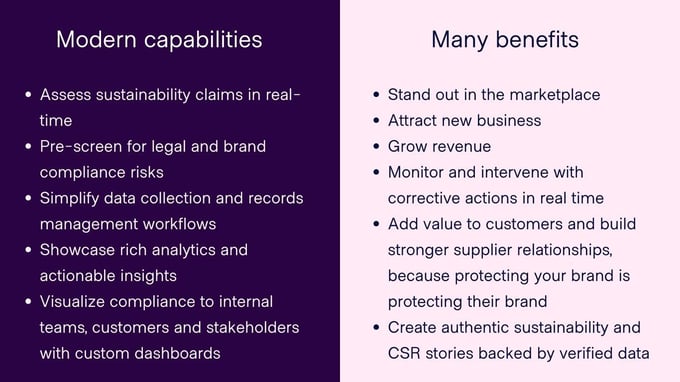

The path forward: bringing your sourcing policy to life is within reach

Sustainable sourcing policies are too important to stay paper tigers. Like food safety, they now demand rigorous, real-time verification. As buyer and consumer expectations grow, technology is evolving to support these requirements at scale and at a cost that makes sense. Here's what is possible today:

As pressure mounts, companies have a choice: continue to treat sustainability as a box-checking exercise, or embrace it as a strategic advantage. The ones that succeed won’t be those with the best-written policies, but those who can prove their policies are alive and in practice with by using verified data and real-time monitoring.

The time to act is now. Your customers, consumers—and ultimately your bottom line—will thank you.

Heading to Boston?

Come find me at SENA March 16-18, and we can talk about how Goldfish can help you reach this now achievable goal or book a meeting with me.

Come find me at SENA March 16-18, and we can talk about how Goldfish can help you reach this now achievable goal or book a meeting with me.